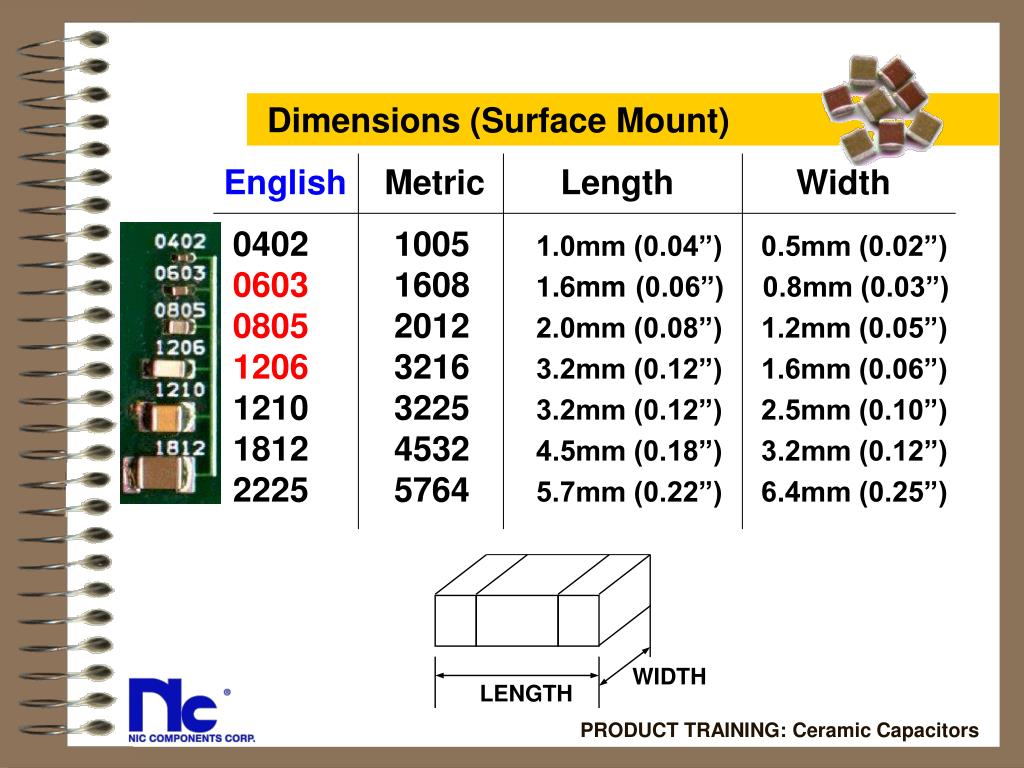

The whole board is then passed through a reflow oven which melts the solder into place, making the contacts.Ī surface mount resistor provides the same functionality as the more traditional axially leaded resistors but has a lower power dissipation capacity and oftentimes a lower stray inductance and capacity.

Solder paste is printed onto the mounting pads of a PCB, and the resistors are placed automatically onto these pads by pick and place equipment. It features the resistance value code printed onto it, where there is space. With class definitions understood you can look how the temperature coefficients break down.A surface mount resistor is a tiny rectangular ceramic body with silver conductive edges on either end. Also referred to as surface mount technology, an SMD resistor offers advantages in saving space on printed circuit boards (PCBs).

They can be substituted with EIA class 2- Y5U/Y5V or Z5U/Z5V capacitorsĬlass IV (or written class 4) ceramic capacitors are barrier layer capacitors which are not standardized anymore Class 1 ceramic caps offer high stability and low losses for resonant circuit applicationsĬlass I ceramic caps offer high stability and low losses for resonant circuit applicationsĬlass 2 ceramic capacitors offer high volumetric efficiency for smoothing, by-pass, coupling and decoupling applicationsĬlass II (or written class 2) ceramic capacitors offer high volumetric efficiency with change of capacitance lower than −15% to +15% and a temperature range greater than −55 ☌ to +125 ☌, for smoothing, by-pass, coupling and decoupling applicationsĬlass 3 ceramic capacitors are barrier layer capacitors which are not standardized anymoreĬlass III (or written class 3) ceramic capacitors offer higher volumetric efficiency than EIA class II and typical change of capacitance by −22% to +56% over a lower temperature range of 10 ☌ to 55 ☌.

0 kommentar(er)

0 kommentar(er)